Hytrans pump units are powered by highly reliable, environmentally compliant diesel engines with state-of-the-art controls to simplify operations and maximize safety. Hytrans pumps consist of HyrdoSubs and AutoBoost units.

The state-of-the-art control systems on Hytrans pump units are based on the latest CAN Bus technology, and are highly robust and reliable. This has been demonstated over and over again for over 30 years in some of the harshest environments on earth (including humid salt air environments near the equator to the frozen tundra of Siberia). Even so, Hytrans knows that if something is going to go wrong, it will likely happen at the worst possible moment (Murphy’s law). As such, most Hytrans systems include:

- Redundant sensors in critical applications

- Permissive controls that allow operators to acknowledge and disable non-critical alarm faults (at which point the system will assume the unit is within safe operating limits)

- Single path, non-looped wiring with non-addressable (non-digital) sensors, solenoids, and actuators. Wireless communication is not utilized with the units.

- A human interface device that will continue to operate, even if the display screen is damaged.

- Customizable programming (available as an option) for owner-specific alarm and shutdown processing

- Wireless control and communications (available as an option) with pump units via radio and cellular technologies

HydroSubs – How Do They Work?

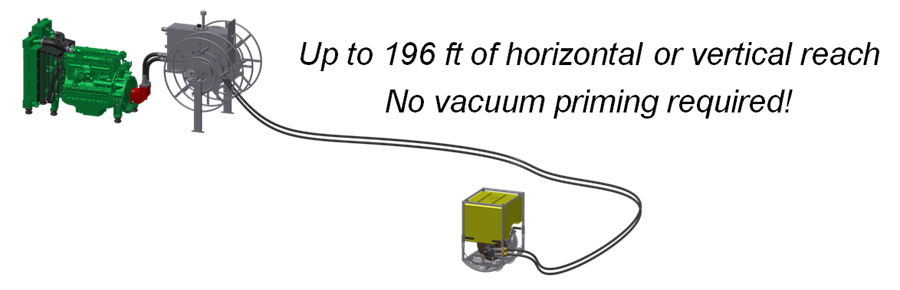

HydroSubs are the most reliable and flexible means of accessing water for fire suppression, flood control and dewatering. As shown in the picture below the heart of the HydroSub is a remote driven, submersible pump (pictures with a yellow float) that is placed directly in the water. Once powered up, the pump instantly begins to push water through the supply hose (not shown), allowing water sources of up to 197 ft, horizontally or vertically, from the power unit to be accessed (unless otherwise noted). Absolutely no vacuum priming is required, improving reliability, minimizing set up time, and freeing up manpower for more important tasks.

The water supply from a HydroSub is always pressurized and no drafting is involved. As a result, any reliable water source within the reach of its power unit can be utilized in pre-lanning and credited as a water supply for ISO grading purposes.

Every Hytrans HydroSub and AutoBoost unit is backed by over three decades of quality improvements, performance enhancements, and experience in a broad range of applications. Hytrans not only talks about high volume water movement, they have the numbers to prove their expertise (as of January 2021):

- Hytrans systems are operational in at least 50 countries with more than 1,200 HydroSubs built to date. This includes:

- Over 100 units with nominal ratings of 6,300 GPM or greater (175 psi discharge @ 49 ft. of lift), and

- Over 50 units with nominal ratings of 3,200 GPM or greater (175 psi discharge @ 49 ft. of lift)

- Thirty-six of the original HS 150’s built for the Dutch government in 1988, including the prototype built in 1986, are still in service today (the retired units were replaced by stationary pumps).

The HydroSub and AutoBoost units are the heart of the integrated water supply systems available through Hytrans Fire Systems. When purchased as an integrated system (pumps, hose, appliances, and hose deployment/recovery systems) the end user can rest assured that all of their equipment will be compatible, function properly and be covered by one warranty policy that provides comprehensive technical and maintenance support services.

HydroSub 60

| Rise to Fire Ground | Impellor | GPM | Usable Hose Length (ft) 5 psi available at end of hose |

||

| 4 in. | 5 in. | 6 in. | |||

| 25 ft | Standard | 400 | 3,200 | 9,800 | 26,000 |

| 600 | 800 | 7,700 | 7,200 | ||

| Hi-Flow | 600 | 2,600 | 7,800 | 20,000 | |

| 1,000 | 100 | 400 | 1,200 | ||

The HS 60 can move 5,283 GPM over short distances and elevation increases with the flood pump attached.

HydroSub 150

| Rise to Fire Ground | Impellor | GPM | Usable Hose Length (ft) 5 psi available at end of hose |

||

| 4 in. | 5 in. | 6 in. | |||

| 25 ft | Standard | 700 | 1,600 | 5,000 | 13,000 |

| 1,100 | 400 | 1,400 | 3,800 | ||

| Hi-Flow | 1,000 | 500 | 1,800 | 4,900 | |

| 2,100 | Not Practical | Not Practical | 200 | ||

The HS 150 can move 13,208 GPM over short distances and elevation increases with the flood pump attached.

HydroSub 150 Dual Feed Pump (DFP)

The unit consists of a HydroSub 150 with two (2) submersible pumps with a four-cylinder 214 HP Volvo Diesel Engine. The unit has a total flow capacity of 6,340 GPM at 29 psi, and comes complete with a hydraulic support winch and powered hose reels. The HS 150-DFP has two support land-based boost pumps (vacuum primed) when obstructions or excessive lifts make draining impractical. The HS 150-DFP has two lightweight portable hydraulic driven submersible pumps (complete with floating device) and is powered by a 214 HP 4-cylinder diesel engine. The unit has 99 ft of hydraulic hose, which enables the submersible pumps to be deployed in difficult access locations. The hydraulic hose is stored on two hydraulic driven hose reels. The unit has a hydraulic driven support winch to retrieve the submersible pumps after deployment. The HS-150-DFP can be delivered on a hook arm frame but can also be delivered separately to be locally installed on a truck or trailer. Standard pump outlets include 8 in. Storz coupling or 10 in. Multilug (others on request). The pumps have stainless-steel pump housings, bronze alloy impeller (suitable for use in seawater), and stainless-steel hydraulic hose swivels. Each pump can be separately engaged. As such, the operator can independently switch each pump on and off by means of a push button. Each submersible weighs approximately 278 lbs, and the total system capacity is 6,340 GPM and 29 psi.

HydroSub 300 Dual Feed Pump (DFP)

The HFS HydroSub-300 is controlled by an easy-to-operate Human Machine Interface and an advanced monitoring system (CAN bus). The HS-300 features portability, quick deployment, and a high flow capacity of 8,000 GPM at 44 psi (+/- 5%). The instrumentation and control panel is fixed on the side of the unit. The ergonomically designed control panel uses advanced electrical technology for operation. The system monitors and maintains all process values (oil temperature, oil pressure, output pressure, etc) to assure safe and reliable behavior of the unit. The unit has two (2) portable floating submersible pumps powered by a hydraulic system where the primary power is generated by a diesel engine.

The unit , herein referred to as the “HydroSub 300,” is in essence, an extremely large capacity pump unit with all the advantages of a portable submersible pump. The submersible pump is a portable centrifugal pump, floating partially or completely in the water, for which the hydraulic power is provided by diesel powered hydraulic pump.

HydroSub 550/AutoBoost 550

| Lift | Rise to Fire Ground | GPM | Usable Hose Length (ft) 5 psi available at end of hose |

||

| 3 X 6 in. | 2 X 8 in. | 1 X 10 in. | |||

| 49 ft | 25 ft | 1,000 | 47,000 | 94,000 | 78,000 |

| 3,900 | 2,700 | 7,400 | 6,000 | ||

| 90 ft | 1,000 | 39,000 | 77,000 | 64,000 | |

| 3,900 | 3,000 | 6,000 | 5,000 | ||

The HS 500 is available with direct injection foam proportioning and remote control.

HydroSub 900/AutoBoost 900

| Lift | Rise to Fire Ground | GPM | Usable Hose Length (ft) 5 psi available at end of hose |

||

| 3 X 8 in. | 2 X 10 in. | 2 X 12 in. | |||

| 49 ft | 25 ft | 3,000 | 26,000 | 37,000 | 84,000 |

| 6,340 | 6,400 | 9,000 | 20,000 | ||

| 90 ft | 3,000 | 21,000 | 30,000 | 69,000 | |

| 6,340 | 5,200 | 7,400 | 17,000 | ||

The HS 900 is available with direct injection foam proportioning and remote control.

HydroSub 1200/AutoBoost 1200

| Lift | Rise to Fire Ground | GPM | Usable Hose Length (ft) 5 psi available at end of hose |

||

| 3 X 8 in. | 2 X 10 in. | 2 X 12 in. | |||

| 32 ft | 25 ft | 4,000 | 15,000 | 21,000 | 49,000 |

| 7,925 | 4,100 | 5,800 | 13,500 | ||

| 90 ft | 4,000 | 12,500 | 17,500 | 40,000 | |

| 7,925 | 3,400 | 4,800 | 11,000 | ||

The HS 1200 is available with direct injection foam proportioning and remote control.

Please, contact HFRC for additional information and details about the available pump units from Hytrans Fire System. Additional information may also be found at Hytrans Fire System (Warning – It’s in metric).

Specialized Pumps

All Hytrans pumps come standard with the submersible pumps shown in the photos above. However, other styles of remote driven pumps are available to satisfy your unusual and specific needs. These pumps include but are not limited to trash, salvage, mud and dredging pumps.

Semi-Fixed and Fixed Pump Installations

Hytrans and HFRC can help you to meet your water supply needs, work around environmental permitting restrictions and avoid costly dock upgrades (to increase weight bearing capacity) by providing fixed and semi-fixed, hydraulically driven pumping systems.